Hubei Weiyu Special Vehicles Co., Ltd is an important branch of CLW

group with registered capital 100, 000, 000 RMB(14 millions US

Dollars) and total capital 6, 000, 000, 000(840 millions US

Dollars). Located in Suizhou city, hubei province, central China,

the Hubei Chengli Special Automobile Co., Ltd is one of the largest

manufacturers authorized by National Ministry of Industry and

Information for production of 800 types of special purpose trucks

and export Center of Trucks and Spare parts identified by Hubei

Province Government, such as Water Tank Truck, Insulation Truck and

Milk Truck, Sewage Suction Truck, Garbage Truck, Man lift

Truck/Aerial Platform Truck, Truck with Crane, Fuel Truck/Trailers,

Chemical Tanker Delivery Truck, Bulk Cement Truck, Concrete Mixer

Truck, Fire Truck, Dump Truck, Van Truck/Refrigerated Truck,

Wrecker/Tow Truck, Flatbed Truck/Low Bed, Tractor, LPG

Tank/Truck/Trailer/Skid Station, Road Sweeper/Cleaning Truck,

Ambulance Trucks, LED Advertising Trucks, RV/Camper Trucks, Food

Truck/Vender Truck and all kinds of special Trailer applied in

sanitation, construction, transportation, chemical, oil and gas,

emergency rescue and so on. With leapfrog development in 16 years

since 2004, now Hubei Chengli Special Automobile Co., Ltd has owned

more than 70 professional workshops for different vehicles and 2

technical centers, more than 12, 600 staffs, in which more than 800

are R&D persons and more than 5000 are technical workers...

The "CLW" brand is honored as the "Hubei Well-kown Trademark",

Hubei Chengli Special Automobile Co., Ltd is certificated by

ISO9001-2015, ISO14001-2005, OHSAS18001, CCC, Automobile Energy

Saving and Environment Protection, Pressure Vessels certificated by

A2 C2 C3, ASME and ADR, more than 100 state owned patents for truck

mounted sewage treatment system and fire truck. Long term

cooperation established with Chinese truck chassis supplier, such

as DONGFENG, FAW, SINOTRUK, FOTON, ISUZU, SHACMAN, JAC, JMC, CAMC

and so on. Hubei Chengli Special Automobile Co., Ltd. Tops No. 1 in

China for water bowser selling in 6 years and No. 1 in China for

Sanitation truck in 3 years; Top 4 in Hubei Private Manufacturing

Companies and Top 500 of China private Companies.

Trucks from Hubei Chengli Special Automobile Co., Ltd have been

sold to more than 29 provinces in China and more than 80 overseas

countries and regions in Asia, Africa, South America, Middle East

and so on, such as Russia, Mogolia, Philippine, Vietnam, Cambodia,

Myanmar, Laos, Kazakhstan, uzbickstan, Kyrghyzstan, Tanzania,

Zambia, Nigeria, Austrilia, Chile, Bolivia, Ethiopia, Sudan,

Malaysia, Congo, El Salvador, Iraq, New Zealand, Chile, Bolivia,

Argentina and so on.

Below are the major products:

Garbage truck

Water tank truck

Fuel tank truck/semi-trailer

Refrigerator truck

Truck mounted crane

Dump truck

Fecal/sewage suction truck

Special cleaning truck

Heavy duty truck crane

Stage truck

Concrete mixer truck

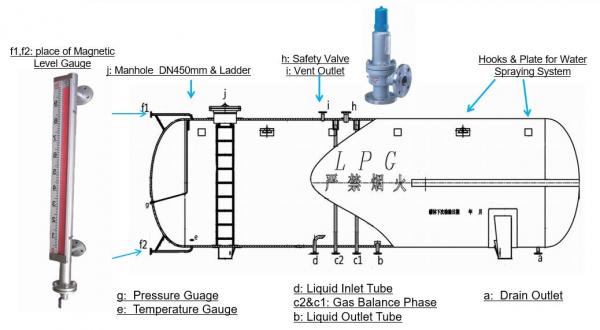

LPG storage tank/bobtail truck/semi-trailer/skid station

Bulk powder transportation truck/trailer

Bulk feed/paddy wheat truck

Road maintenance truck

High altitude truck

LED advertisement truck

Road sweeper truck/cleaning truck

Wrecker/Towing truck